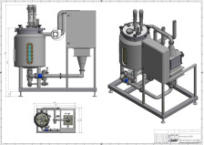

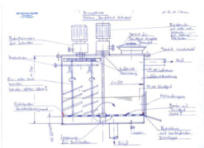

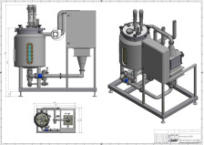

Flexibility and open to new ideas

We always come up with the right solution and are happy to design your installation

according to your requirements.

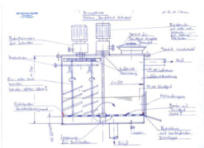

Control example

The mbt brewery controls – our controls developed specifically for breweries and

brewhouses. All our controls used include a curve visualization and curve tracing.

All temperature profiles are recorded and saved. Readout of the

data can easily be made on a stick or via an interface for existing automation or

computer.

There is a variety of additional options (e. g. integration of existing equipment)

available to meet customer demands for both control options, mbt-smartbrew X

and mbt smartbrew L. mbt has developed a brewhouse and brewery control – in

cooperation with its partner – specifically for restaurant breweries, small and

medium-sized breweries: mbt-Combi-Line-Steuerung.

This user-friendly and clear control is characterized by its easy operation and

programming for the brewer. All input and recipes are entered on a touchscreen

(available 10” to 19”). The individually designed brewing installation is shown

completely on the display. All fittings, valves, pumps, engines, and pipelines are

visually pictured on the display. With a simple touch on the display you can operate

engines, control pumps and start control valves. Temperature control of the mash

or wort kettle can also easily be made with a few handles. With a clear program

overview the individual recipes can be accessed, changed and started. After

starting the recipe, the control then manages all information like temperature, types

of heating up, rest times, agitator speed, etc. Manual operations and sequence

changes can be made at any time during the ongoing process.

Another highlight is the standardly configured remote maintenance which allows us

to access the brewing equipment control from the mbt offices and help from afar or

conduct program changes. This makes quick action and help for our customers in

an emergency possible and saves unnecessary costs. In addition to the brewing

equipment you can also manage the fermenting and storage tanks with the control.

There is a fermentation preprogrammed and can easily be adjusted by the user. On

request you can get your personal access to the remote control.

Planning on building a brewery?

We are glad to noncommittally advise you on your

project, no matter if you are interested in new

construction, conversion or expansion.

Contact us

You are in concrete need? Feel free to contact us,

especially if you have an idea or vision!

mbt-brautechnik GmbH & Co. KG

Gewerbering Süd 7a

97359 Schwarzach am Main

t: +49 (0)9324 - 9 82 81 50

info@mbt-brautechnik.de

info@mbt-brautechnik.de

Ask for documentary.

We are just one email away.

Information

Brewing technique out of passion

Flexibility and open to new ideas

We always come up with the right solution and

are happy to design your installation according to

your requirements.

Control example

The mbt brewery controls – our controls developed

specifically for breweries and brewhouses. All our

controls used include a curve visualization and curve

tracing. All temperature profiles are recorded and

saved. Readout of the data can easily be made on a

stick or via an interface for existing automation or

computer.

There is a variety of additional options

(e. g. integration of existing equipment) available to

meet customer demands for both control options,

mbt-smartbrew X and mbt smartbrew L. mbt has

developed a brewhouse and brewery control – in

cooperation with its partner – specifically for

restaurant breweries, small and medium-sized

breweries: mbt-Combi-Line-Steuerung.

This user-friendly and clear control is characterized

by its easy operation and programming for the

brewer. All input and recipes are entered on a

touchscreen (available 10” to 19”). The individually

designed brewing installation is shown completely on

the display. All fittings, valves, pumps, engines, and

pipelines are visually pictured on the display. With a

simple touch on the display you can operate engines,

control pumps and start control valves. Temperature

control of the mash or wort kettle can also easily be

made with a few handles. With a clear program

overview the individual recipes can be accessed,

changed and started. After starting the recipe, the

control then manages all information like

temperature, types of heating up, rest times, agitator

speed, etc. Manual operations and sequence

changes can be made at any time during the ongoing

process.

Another highlight is the standardly configured remote

maintenance which allows us to access the brewing

equipment control from the mbt offices and help from

afar or conduct program changes. This makes quick

action and help for our customers in an emergency

possible and saves unnecessary costs. In addition to

the brewing equipment you can also manage the

fermenting and storage tanks with the control. There

is a fermentation preprogrammed and can easily be

adjusted by the user. On request you can get your

personal access to the remote control.

Information

Contact us

You are in concrete need? Feel free to contact us,

especially if you have an idea or vision!

mbt-brautechnik GmbH & Co. KG

Gewerbering Süd 7a

97359 Schwarzach am Main

t: +49 (0)9324 - 9 82 81 50

info@mbt-brautechnik.de

Ask for documentary.

We are just one email away.

Planning on building a brewery?

We are glad to noncommittally advise you on your

project, no matter if you are interested in new

construction, conversion or expansion.

Brewing technique out of passion