Our products have rhyme and reason.

You have our word on it.

mbt Brautechnik serves you from the beginning. We plan and manufacture detailed solutions to turnkey breweries. Contact us regarding your ideas and we are happy to develop the right solution with you:Fairs and press

Things are on the move at mbt and some ideas even attract interest outside the sector and have been published in the local press. We are happy to help you should you have any questions.Control and electrical installations

All controls used include a curve visualization and curve tracing. Our controls are customized for your brewery and programmed by our own software department.Projects and ideas.

We are happy to advise you and support you with your project. We adjust all eventualities in advance whereby we can provide smooth operation. In the past we wouldn’t have dreamed of being able to share our knowledge and proficiency with the whole world today.Small malting

The malting is specifically designed for laboratories and institutes for experimental and teaching purposes. The malting is designed as a one-tank-malting. Fills are possible from 10 kg to 100 kg.Planning

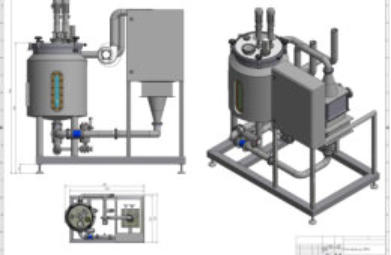

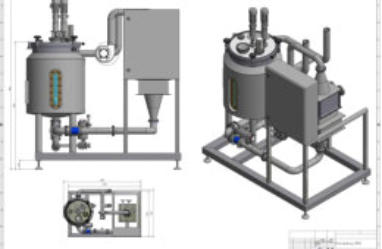

We support you in the planning of your brewery or brewing plant starting from the first idea to your first self-brewed beer. We develop flow charts and plan your whole brewery in 3D with modern CAD technology (AutoCAD Inventor Routed Systems). Your ideas compared with our experience and know how promise a successful project. We prepare for you: • Strain plans • Layouts • Care and disposal data (evaluation) • Consumption volume • Room schedules and much more. Everything at a glance: We prepare everything that is essential from the beginning to be able to set up your brewery technically sound. Like that, your approval procedure is certainly going to be a success.Brewing plants

The planning of a brewery from the offer to the realization and the final costumer acceptance is our biggest passion. The service at mbt goes way beyond the usual process. From the beginning on we always think one step ahead. A one-stop-service: a brewing plant for every brewing process, e. g. a restaurant brewery like a large brewery. Our brewing plants are designed according to the most modern state of the art. A production with various brew (up to 10 brews in 24h) is easily possible.

Planning on building a brewery?

We are glad to noncommittally advise you on your

project, no matter if you are interested in new

construction, conversion or expansion.

Contact us

You are in concrete need? Feel free to contact us,

especially if you have an idea or vision!

mbt-brautechnik GmbH & Co. KG

Gewerbering Süd 7a

97359 Schwarzach am Main

t: +49 (0)9324 - 9 82 81 50

info@mbt-brautechnik.de

info@mbt-brautechnik.de

Ask for documentary.

We are just one email away.

Control cabinets

wiring, brewing plants, optimization

Brewing installations

Up to 50.000 hectolitre p. a., brewing sequences up to 10 brews in 24h,

bottle and can fillers for small bottling volumes and units.

Water treatment plants

for the optimal brewing water of the highest quality

Engineering performance energy

warmth, supply and disposal

Architecture services

planning and surveying

Gastronomic concepts

Mini-Brew

Staff training on site

Master brewer service / interim master brewer technology consulting

Delivery of

ice water tanks and cooling systems, ZKG tanks, storage tanks,

fermentation tank, malt plants and malt mills

Analysis and optimization

of your lauter tun

Filling plants

for bottles and KEG, labeller and packager

Cleaning plants

for bottles and KEG CIP-system

Your benefit:

A huge time-saver and a higher wort quantity. Like that, you can do two brews in about 10 hours (AM = 1000 litres) with a 500-litre

brewing plant. With a brewery that is designed that way, it is possible to do four brews in 24 hours (AM = 2000 litres).

Brewing plant / restaurant brewery equipment and size characteristics

Brewing plant with and without control

All brewing plants are manufactured according to industry standards and all restaurant brewery tanks are sanded or clad with

copper on request. All fittings, pumps and coolers are from renowned manufacturers that also supply the large-scale industry. We

also supply brewing plants as complete package from the grinding mill to the cylindrical-conical fermentation tank and the storage

cellar in copper or stainless steel.

We are happy to plan and realize your dream brewing plant for you.

Bottle filler

mbt-brautechnik provides you with the right bottle filler for your requirements. The newest generation of bottle fillers, model VAF-4.0, will delight you. Trouble-free handling and flexible container sizes …

Overview

Brewing technique out of passion

Fairs and press

Things are on the move at mbt and some ideas even attract interest outside the sector and have been published in the local press. We are happy to help you should you have any questions.

Control and electrical installations

All controls used include a curve visualization and curve tracing. Our controls are customized for your brewery and programmed by our own software department.

Projects and ideas.

We are happy to advise you and support you with your project. We adjust all eventualities in advance whereby we can provide smooth operation. In the past we wouldn’t have dreamed of being able to share our knowledge and proficiency with the whole world today.

Small malting

The malting is specifically designed for laboratories and institutes for experimental and teaching purposes. The malting is designed as a one-tank-malting. Fills are possible from 10 kg to 100 kg.

Planning

We support you in the planning of your brewery or brewing plant starting from the first idea to your first self-brewed beer. We develop flow charts and plan your whole brewery in 3D with modern CAD technology (AutoCAD Inventor Routed Systems). Your ideas compared with our experience and know how promise a successful project. We prepare for you: • Strain plans • Layouts • Care and disposal data (evaluation) • Consumption volume • Room schedules and much more. Everything at a glance: We prepare everything that is essential from theOur products have rhyme and reason.

You have our word on it.

mbt Brautechnik serves you from the beginning. We plan and manufacture detailed solutions to turnkey breweries. Contact us regarding your ideas and we are happy to develop the right solution with you:

Brewing plants

The planning of a brewery from the offer to the realization and the final costumer acceptance is our biggest passion. The service at mbt goes way beyond the usual process. From the beginning on we always think one step ahead. A one-stop-service: a brewing plant for every brewing process, e. g. a restaurant brewery like a large brewery. Our brewing plants are designed according to the most modern state of the art. A production with various brew (up to 10 brews in 24h) is easily possible.

Your benefit:

A huge time-saver and a higher wort quantity.

Like that, you can do two brews in about 10 hours

(AM = 1000 litres) with a 500-litre brewing plant. With

a brewery that is designed that way, it is possible to

do four brews in 24 hours

(AM = 2000 litres).

Brewing plant / restaurant brewery equipment

and size characteristics

Brewing plant with and without control

All brewing plants are manufactured according to

industry standards and all restaurant brewery tanks

are sanded or clad with copper on request. All fittings,

pumps and coolers are from renowned

manufacturers that also supply the large-scale

industry. We also supply brewing plants as complete

package from the grinding mill to the cylindrical-

conical fermentation tank and the storage cellar in

copper or stainless steel.

We are happy to plan and realize your dream

brewing plant for you.

Bottle filler

mbt-brautechnik provides you with the right bottle filler for your requirements. The newest generation of bottle fillers, model VAF-4.0, will delight you. Trouble- free handling and flexible container sizes …

Overview

Control cabinets

wiring, brewing plants, optimization

Brewing installations

Up to 50.000 hectolitre p. a., brewing sequences

up to 10 brews in 24h, bottle and can fillers for

small bottling volumes and units.

Water treatment plants

for the optimal brewing water of the highest

quality

Engineering performance energy

warmth, supply and disposal

Architecture services

planning and surveying

Gastronomic concepts

Mini-Brew

Staff training on site

Master brewer service / interim master brewer

technology consulting

Filling plants

for bottles and KEG, labeller and packager

Delivery of

ice water tanks and cooling systems, ZKG tanks,

storage tanks,fermentation tank, malt plants and

malt mills

Analysis and optimization

of your lauter tun

Cleaning plants

for bottles and KEG CIP-system

Brewing technique out of passion

Contact us

You are in concrete need? Feel free to contact us,

especially if you have an idea or vision!

mbt-brautechnik GmbH & Co. KG

Gewerbering Süd 7a

97359 Schwarzach am Main

t: +49 (0)9324 - 9 82 81 50

info@mbt-brautechnik.de

Ask for documentary.

We are just one email away.

Planning on building a brewery?

We are glad to noncommittally advise you on your

project, no matter if you are interested in new

construction, conversion or expansion.